What is boiler plate steel?

Boiler steel plate is one of the very key materials in boiler manufacturing, mainly refers to the hot-rolled special carbon steel and low alloy heat-resistant steel plate materials used to manufacture boiler shell, cylinder, header box end cover, support hangers and other important parts.

Boiler steel plate is often in the middle, high temperature and high pressure condition, in addition to withstand high temperature and pressure, but also by the impact, fatigue load and water and gas corrosion, working conditions are poor. If the boiler in the use of destructive accidents will cause serious losses.

Therefore, the boiler steel plate must have good physical properties, mechanical properties and processability, and in the technical provisions of the material standards to give strict provisions to meet the safety of its use.

What kind of steel is used in boilers? Classification of boiler plate steel

Classification by material

From the material, boiler steel plate can be divided into two categories: special carbon steel plate and low alloy heat-resistant steel plate.

The materials used for boiler plate have strict control on chemical composition, especially on harmful elements such as phosphorus, sulfur and residual elements such as chromium, nickel and copper;

Smelting should also be good deoxidation and removal of non-metallic inclusions to ensure good plasticity and toughness;

The organizational structure requires uniformity, and the grain size is controlled within a certain range (usually the grain size is desired to be between 3 and 7 levels);

There are also strict requirements for surface quality and internal defects;

In addition room temperature and high temperature mechanical properties must be guaranteed.

In GB/T713-2014 "boiler and pressure vessel steel plate" standard clearly stipulates that the oxygen converter or electric furnace should be used for smelting and should be refined outside the furnace, while the manufacturing process should also ensure that the continuous casting billet matter ingot compression ratio in hot rolling is not less than 3.

Classification according to the use of the environment

According to different working conditions, boiler steel plate can be divided into manufacturing room temperature and medium temperature pressurized parts steel plate and manufacturing high temperature pressurized parts steel plate two categories.

Boiler steel plates for room temperature and medium temperature (below creep temperature) are mostly made of carbon steel, including carbon steel, carbon-manganese steel, carbon-manganese-silicon steel, etc., i.e., Q245R and Q345R in GB/T713-2014 "Steel Plates for Boilers and Pressure Vessels" (in GB/T713-1997 "Steel Plates for Boilers", 20g, 22Mng, 16Mng, and 19Mng steels), as well as ASME SA-515/SA-515M Carbon Steel Plates for Medium and High Temperature Pressure Vessels, SA-299/SA-299M Carbon Manganese Silicon Steel Plates for Pressure Vessels. It is mainly used for manufacturing boiler barrels, collector box end caps below medium temperature and other pressure-bearing parts.

Room temperature and medium temperature boiler steel requires that it should have

Higher room temperature strength;

Good impact toughness and low notch sensitivity;

Good ageing toughness is also required due to the large amount of cold deformation required in the processing of components such as pot barrels;

Good machinability and weldability;

Good low times the organization and so on.

High temperature (creep temperature above) with boiler steel plate, generally low alloy heat-resistant steel, commonly used chromium-molybdenum steel, chromium-molybdenum-vanadium steel, chromium-molybdenum-tungsten steel, etc.. Mainly used in the manufacture of high-temperature header end caps, steam pipe plug plate and other high-temperature pressurized parts.

For example, GB713-2014 boiler steel plate in the 15CrMoR, 12Cr1MoVR and the United States ASME SA-387/SA387 M pressure vessels with chromium - molybdenum Alloy steel plate Gr22, Gr91 and ASME SA1017/SA1017M pressure vessels with chromium - molybdenum - tungsten alloy steel plate Gr23, Gr911, Gr122 steel, etc.

Boiler steel plate for high temperature requires that it must have:

Sufficient high temperature enduring strength and enduring plasticity;

Good high temperature organizational stability;

Good high temperature oxidation resistance (heat resistance);

Good hot and cold processing technology (mainly refers to the cold bending deformation and weldability) and so on.

Main characteristics of boiler steel plate

Boiler steel plate material characteristics

1. high strength: the strength of boiler steel plate is much higher than ordinary steel plate, in good welding conditions to meet the needs of high strength and high toughness.

2. good heat resistance: boiler steel plate can maintain a certain degree of strength and toughness at high temperatures, and can withstand high temperature and high pressure environment.

3. excellent corrosion resistance: boiler steel plate can be used in harsh chemical environments for a long time to prevent internal corrosion and damage to boiler equipment.

4. Good weldability: boiler steel plate has good weldability, which makes the production and maintenance of boiler equipment easier.

5. Easy to process: Boiler steel plate is easy to cut and processed into various shapes required, making the production process more convenient and flexible.

The main use of boiler steel plate

Widely used in petroleum, chemical, power station, boiler and other industries, used to make reactors, heat exchangers, separators, ball tanks, oil and gas tanks, liquefied gas tanks, nuclear power reactor pressure shell, boiler steam packages, liquefied petroleum gas cylinders, hydroelectric power station high-pressure water pipes, water turbine turbine shells and other equipment and components.

How thick is a boiler plate steel?

What grade steel is boiler plate?

There are various types and specifications of boiler plate, and the type of steel varies according to different standards and applications. The following are typical representatives under each type of standard:

Chinese National Standard:

Q245R, Q345R, Q370R: For general pressure vessels.

16MnDR, 15CrMoR: Resistant to low temperature and high pressure.

09MnNiDR, 12MnNiVR: For high pressure and low temperature environment.

Others such as 14Cr1MoR, 12Cr2Mo1R, 13MnNiMoR meet specific strength and corrosion resistance requirements.

European Standard:

P265GH, P295GH: High temperature and corrosion resistant.

P275NH, P355GH: For pressure vessels and high strength structures.

P460NH, for example, has high requirements for strength and toughness.

A516 / SA516:Boiler and pressure vessel quality steel plate with improved notch toughness for low to moderate services.

American Standard:

SA515Gr60/65/70: High temperature resistance and high strength.

SA285GrC, A537CL: Suitable for industrial pressure vessels.

Japanese Standard:

SB410, SPV355: High strength and corrosion resistance.

SB450: Specialized for high temperature and pressure vessels.

German Standard:

19Mn6, 15Mo3: High strength and corrosion resistant materials.

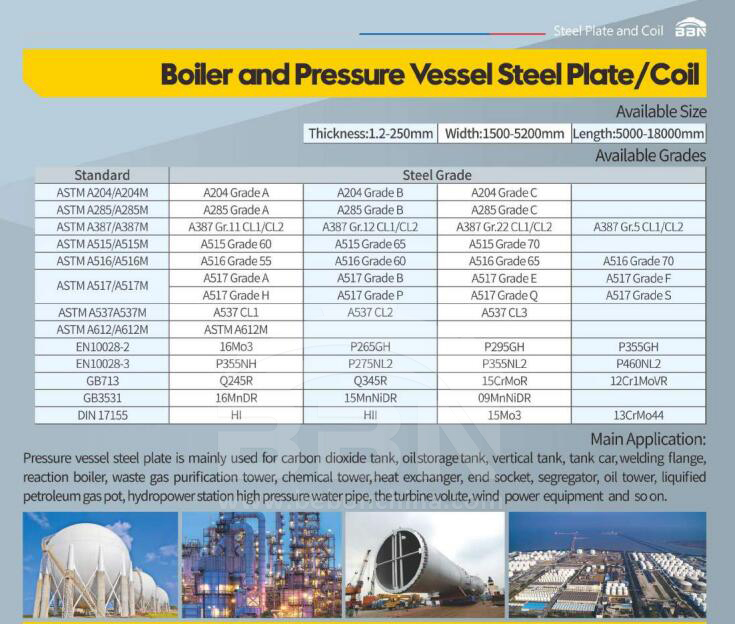

In addition to the above list, there are also many domestic and foreign boiler vessel plate models in the market, whose specifications are usually: thickness range (8-300) mm, width range (1500-4020) mm, length range (5000-18800) mm. If you need detailed consultation, please feel free to contact BBN steel.

The pipes produced by BBN Steel are of reliable quality and the raw materials used are strictly in accordance with standards. We have very rich experience in manufacturing pipes for boilers and can meet the various needs of different customers at reasonable prices. Welcome to ask for quotations.

Just like you, 70% customers choose long-term cooperation with BBN steel not only for our good product and service quality, good reputation in the international market, but also for our experienced one-stop raw material supply and further steel processing!