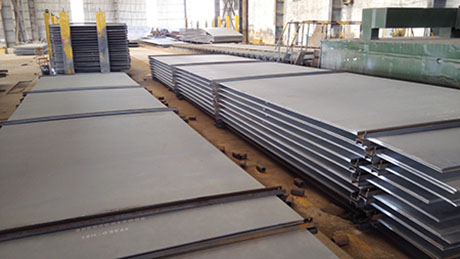

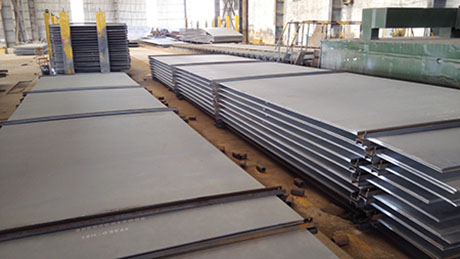

Material: Q420R

Executive standard: GB713-2014

Q420R plate specification: 8-320mm Q420R width: 1500-4200 Q420R length: 6000mm over

Q420R steel plates cutting, drilling, welding service

Q420R steel plates storage: Bebon Steel

Q420R manufacturing method Steel is smelted by oxygen converter or electric furnace, and should be refined outside the furnace. The compression ratio of continuous casting slab and steel ingot is not less than 3; the compression ratio of electroslag remelting slab is not less than

Q420R steel mechanical properties and process properties

| Grade |

Delivery condition |

Thickness |

Tensile strength |

Impact test |

Bending test |

Rm

/MPa |

ReLa

/MPa |

A

/% |

temperature

/℃ |

KV2

/J |

180°

b=2a |

| Q420R |

normalized |

10-20 |

≤590~720 |

≤420 |

≤18 |

≤-20 |

≤60 |

≤d=3a |

| normalized |

>20~30 |

≤570~700 |

≤400 |

Q420R steel plates cutting:The Q420R steel sheets and plates shall be delivered in a sheared or flame-cut state. When the equipment capacity is limited, with the consent of the acquirer and stated in the contract, delivery in the burr state is allowed. The surface of the steel sheet is not allowed to have defects that are harmful to use, such as cracks, bubbles, scarring, folding and inclusion. There shall be no delamination on the side of the steel plate. If the above surface defects are allowed, cleaning is allowed. The cleaning depth is calculated from the actual size of the steel plate, and must not exceed half of the thickness tolerance of the steel plate, and the minimum thickness of the steel plate should be guaranteed. Defects should be cleaned without edges. Other defects are allowed, the depth of which is calculated from the actual size of the steel plate, and must not exceed half of the allowable thickness tolerance, and the thickness of the steel plate at the defect must not be less than the minimum allowable thickness of the steel plate.

Are you also interested in further steel processing (machining)?

Just like you, 70% customers choose long-term cooperation with BBN steel not only for our good product and service quality, good reputation in the international market, but also for our experienced one-stop raw material supply and further steel processing!

Fabrication and Machining Service24h Technical support